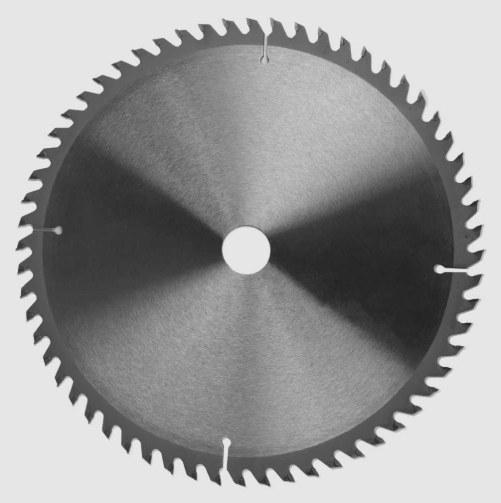

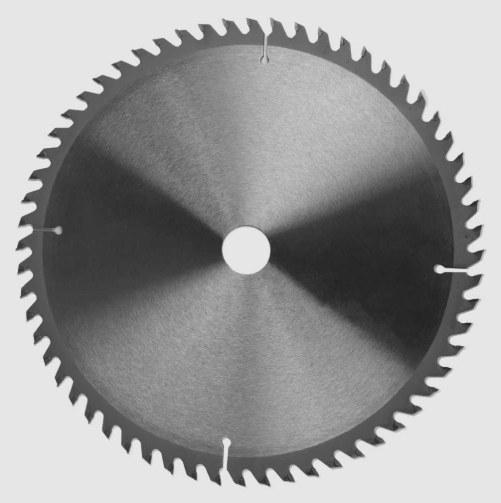

Efficiency, accuracy, and durability are key factors influencing productivity and material quality. Among the many options available, the TCT Circular Saw Blade, such as those developed by Fangda Tools, has emerged as a reliable solution for professional workshops, construction projects, and manufacturing lines. Rather than focusing on exaggerated claims, this article explores how the design and engineering behind TCT blades contribute to consistent cutting results, versatility, and long-term performance.

What Makes a TCT Circular Saw Blade the Best Choice for Precision Cutting?

A Tungsten Carbide Tipped (TCT) circular saw blade is engineered with cutting teeth that contain carbide tips bonded to a steel body. This combination brings together the flexibility of steel and the toughness of tungsten carbide, resulting in a tool that can sustain demanding workloads while maintaining sharpness over extended use.

- Advanced Tooth Geometry: The cutting edge design is not arbitrary. The angle, spacing, and shape of each tooth are carefully optimized to ensure smooth engagement with the material. This geometry reduces vibration, minimizes heat buildup, and lowers the chance of chipping. As a result, users achieve uniform cuts, reduced material waste, and improved surface finishes.

- Heat Resistance and Dimensional Stability: Precision cutting often depends on maintaining blade shape even under high-speed rotation. The steel core of a TCT blade is thermally treated to maintain stability, preventing warping or deformation. Tungsten carbide's high melting point and hardness allow the teeth to resist wear and retain sharpness, which is particularly valuable in repetitive industrial operations.

- Clean Cutting and Reduced Finishing Needs: When used properly, a TCT circular saw blade leaves a clean edge that requires minimal sanding or deburring. This is an important consideration for manufacturers who prioritize time efficiency and material conservation. A smoother cut also contributes to better bonding in subsequent processes such as welding, coating, or assembly.

How Does a TCT Circular Saw Blade Outperform Traditional Steel Blades?

Traditional steel blades have long been a standard tool in workshops, but advances in material science have highlighted their limitations in comparison with TCT blades. While steel blades can deliver acceptable performance in soft materials, their edge retention is often shorter, leading to frequent sharpening and downtime.

- Wear Resistance: The core advantage of a TCT blade lies in the hardness of tungsten carbide, which is significantly higher than that of conventional steel. This difference allows the cutting edges to stay sharper for a longer time, reducing maintenance intervals and extending the overall service life of the blade.

- Lower Heat Generation: Friction and temperature rise are major factors that affect cutting performance. The smooth tooth profile and material composition of a TCT blade contribute to lower heat accumulation, preserving both the blade's integrity and the workpiece's quality. Cooler cutting conditions also enhance operator safety and reduce the likelihood of burns or warping on the cut surface.

- Consistency in High-Volume Operations: In automated production environments, consistency matters more than speed alone. Because TCT blades maintain their sharpness longer, they produce stable results across extended production runs. This uniformity leads to fewer rejected parts and greater process efficiency, especially in metal fabrication, wood processing, and composite cutting industries.

- Cost Efficiency Over Time: Although the initial investment in a TCT circular saw blade may be higher than a basic steel blade, the reduced frequency of replacements and sharpening lowers long-term costs. For companies managing multiple cutting lines, this translates to tangible operational savings.

Which Materials Can You Cut Efficiently with a TCT Circular Saw Blade?

The true versatility of TCT blades is evident in their ability to handle a wide range of materials. From hardwoods to non-ferrous metals, these blades adapt to various cutting tasks without requiring multiple tool changes.

|

Material Type

|

Common Applications

|

Key Benefits of TCT Blade Use

|

|

Hardwood & Softwood

|

Furniture, Flooring, Construction

|

Smooth edges, reduced splintering

|

|

Aluminum & Copper

|

Window frames, Panels, Pipes

|

Precise cutting, low burr formation

|

|

Plastic & PVC

|

Electrical conduits, Sign boards

|

Clean surface, minimal melting

|

|

Laminated Boards

|

Cabinets, Interior panels

|

Fine finishes, accurate angles

|

|

Mild Steel & Stainless Alloys

|

Industrial frames, Automotive parts

|

Controlled cutting speed, extended blade life

|

- Wood and Composites: For carpenters and furniture makers, TCT blades offer a dependable solution for cutting hardwood, plywood, MDF, and laminate. The carbide tips resist dulling from resin buildup and fiber density variations, ensuring continuous cutting performance.

- Non-Ferrous Metals: In applications involving aluminum or copper, TCT blades minimize the burrs that often appear with traditional saws. This is critical in industries like window fabrication or electrical engineering, where smooth edges support safe and precise assembly.

- Plastics and Composites: Plastic materials can deform or melt when exposed to excessive heat. The efficient chip removal and stable cutting action of TCT blades reduce frictional heat, resulting in cleaner cuts and lower material loss.

- Industrial Metal Cutting: For specific TCT models designed for mild steel and similar alloys, users experience reliable cutting at moderate feed rates. These blades help maintain edge integrity even after repetitive cycles, making them valuable for fabrication lines that prioritize accuracy.

Design Innovations in Modern TCT Circular Saw Blades

Companies such as Fangda Tools continue to invest in improving the structure and material performance of TCT blades. Some current advancements include:

- Laser-cut expansion slots: These reduce vibration and maintain balance during high-speed rotation.

- Anti-friction coatings: Applied to minimize material adhesion and improve chip removal.

- Sound-dampening designs: Engineered to reduce noise levels in workshops, improving the working environment.

- Customized tooth profiles: Tailored for specific materials or cutting directions, such as rip or cross cuts.

Such enhancements allow professionals to optimize performance according to their specific production needs while maintaining safety and precision.

Environmental and Safety Considerations

Beyond cutting quality, sustainability and workplace safety are increasingly important. TCT blades contribute positively to these areas by offering longer service life and reduced waste generation. Fewer replacements mean less metal consumption and lower energy use in production and transport. Furthermore, their efficient design reduces the likelihood of sparks or overheating, minimizing risks in industrial environments.

Proper use and maintenance—such as ensuring correct feed rates, cleaning resin deposits, and storing blades in dry conditions—can further extend lifespan and reduce material waste. Regular inspection also helps identify any wear patterns early, preventing potential accidents or tool damage.

The Role of TCT Blades in Automated and Digital Manufacturing

As industries transition toward automation and precision engineering, cutting tools must evolve to meet stricter dimensional and quality requirements. TCT circular saw blades fit naturally into this shift, offering compatibility with CNC systems, robotic saw units, and automated feed lines. Their consistent performance supports repeatable cutting parameters, which are essential in digital production environments.

Moreover, with the integration of data monitoring systems, some advanced cutting machines can track blade temperature, speed, and vibration. This allows predictive maintenance and ensures that every blade operates within optimal conditions.

A Balanced Approach to Cutting Efficiency

The TCT circular saw blade exemplifies how modern engineering transforms a traditional tool into a high-performance solution for diverse industries. By combining material innovation, precise design, and process adaptability, it delivers consistent results without relying on exaggerated claims.

Fangda Tools and similar manufacturers continue to refine these blades through research and technological development, focusing on stability, durability, and user safety. For professionals in woodworking, metal fabrication, or construction, adopting TCT technology represents a logical step toward achieving higher cutting accuracy, reduced downtime, and improved operational sustainability.

Whether used in large-scale manufacturing or specialized craft applications, the TCT circular saw blade demonstrates that precision and reliability can coexist in a single, well-designed tool.