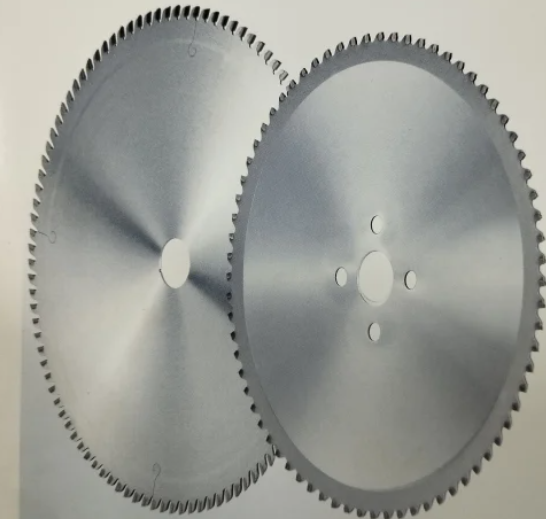

In woodworking, metal processing, and construction material cutting, the TCT Circular Saw Blade remains a core tool for efficient and precise cutting. With tungsten carbide-tipped teeth, it offers enhanced durability and sharpness. However, even the most durable blades will eventually wear out. So how do you know when it's time to replace your TCT blade? This is a key concern for many professionals.

When to Replace a TCT Blade: 3 Key Indicators

Although TCT blades are known for their wear resistance, intensive industrial use inevitably leads to wear and performance decline. Below are three commonly accepted industry criteria for determining whether a TCT blade needs replacement:

| Indicator |

Typical Signs |

Explanatio |

| Tooth Wear |

Dull edges, chipped tips, blackened or burned edges |

Indicates that the carbide layer is worn down or heat-damaged |

| Decline in Cut Quality |

Frayed edges, burn marks, uneven surfaces |

Blade is losing sharpness, resulting in poor cut finish |

| Reduced Efficiency |

Slower cutting speed, increased machine load |

More friction on blade surface, affecting motor performance |

What Affects the Lifespan of a TCT Blade?

1. Material Type

Different materials impose varying levels of stress on the blade:

High-density materials (e.g., hardwood, aluminum alloy) accelerate tooth wear.

Resin-based composites (e.g., OSB boards) tend to cause gumming, requiring frequent cleaning.

2. Operating Practices

Incorrect RPM settings:

Excessively high RPM can cause overheating; too low leads to added friction.

Improper feed rate:

Feeding too fast may chip the teeth; too slow increases abrasive wear.

3. Maintenance Habits

Poor cleaning:

Resin and chip buildup can obstruct heat dissipation and wear the teeth faster.

Improper storage:

Damp environments may cause rusting on the blade body and reduce lifespan.

Regrinding vs Replacement: How to Decide?

For cost-sensitive operations, regrinding TCT saw blades is a practical way to reduce expenses. However, several principles must be followed:

Regrinding should not exceed 30% of the original tooth height.

Precision equipment must be used to restore the tooth geometry and angle accurately.

If cracks, tooth loosening, or structural damage are detected, the blade must be scrapped immediately to prevent safety risks.

Economic Comparison: Regrinding vs Replacement

| Condition |

Regrinding Cost (Estimate) |

New Blade Cost (Estimate) |

Recommended Action |

| Moderate Wear |

¥20–30 per blade |

¥100–300 per blade |

Regrind once if base remains intact |

| Severe Wear |

Not effective |

– |

Recommend full replacement |

| Tooth Damage |

Not repairable |

– |

Must replace |

Practical Tips for Extending TCT Blade Lifespan

1. Regular Inspection and Maintenance: Prevention is Better than Repair

The first step in blade maintenance is routine inspection and cleaning. Users are encouraged to establish a daily-weekly-monthly maintenance plan to reduce premature failure risks.

Daily Maintenance (After Every 8-Hour Shift):

Use a steel wire brush or dedicated cleaner to thoroughly remove sawdust, adhesive residue, or metal chips between the teeth. This prevents overheating due to poor heat dissipation or increased friction.

Check for chipped teeth, visible cracks, or discoloration at the tooth tips. If any are present, stop operation and replace immediately.

Weekly Checks:

Use a dial indicator and fixture to inspect flatness and radial runout. Tolerances should be within ±0.1 mm. Excessive runout can lead to inaccurate cuts, vibrations, and increased noise.

Check for wear in mounting holes, ensure all screws are tight, and the blade is mounted securely.

Proactive inspections allow early intervention before problems escalate, avoiding equipment damage and material waste.

2. Optimize Cutting Parameters: Match the Material, Maximize Life

Different materials have vastly different properties. Using one-size-fits-all cutting parameters is ineffective. Adjusting spindle speed and feed rate based on material can significantly improve both cutting efficiency and blade life.

| Material |

Recommended RPM |

Suggested Feed Speed |

Additional Measures |

| Wood |

3000–5000 |

Medium, steady fee |

Dry cutting, ensure chip clearance |

| Aluminum |

1500–2500 |

Slow, stable feed |

Use lubricant/coolant |

| Plastic |

2000–3500 |

Avoid high-speed melting |

Medium speed with adequate cooling |

| Stainless Steel |

≤1800 |

Very slow, controlled feed |

Strong cooling, low-speed cutting |

Improper cutting parameters are often the "invisible killer" of saw blade life—especially when cutting adhesive-heavy boards or aluminum at high speed, where tooth tips may gum up, blocking chip flow and reducing cooling efficiency.

3. Use Professional Regrinding Services: Reuse, Reduce, Save

TCT blades are not disposable. With proper regrinding, their life cycle can be significantly extended and cost-efficiency improved.

When to Regrind?

When teeth become dull but the base plate is intact, regrinding is viable.

Each blade can typically be reconditioned 2–3 times, assuming it has been well-maintained between uses.

Standard Regrinding Process:

Edge Re-sharpening – Restore cutting angle (usually 15–20°).

Tooth Profile Reshaping – Maintain consistency across all teeth.

Dynamic Balancing – Ensure stable rotation to protect machine spindle life.

Optional Coating – Some high-end services offer wear-resistant coatings for extended performance.

Warning:

If the blade shows cracks, burned tooth roots, or loose teeth, do not attempt to regrind—scrap the blade immediately.

Recognize Warning Signs, Manage Scientifically

The condition of your TCT Circular Saw Blade directly impacts cutting efficiency, product quality, and equipment safety. Operators should develop a basic understanding of blade performance and manage replacement based on usage records and real-time condition monitoring.

Once noticeable dullness or cutting irregularities occur, do not force usage. Prompt maintenance or replacement is critical.

Final Thoughts

In the era of smart manufacturing and lean management, refined tool management is vital for maximizing output and ensuring quality control. While small in size, saw blades carry significant responsibilities—timely replacement is a safeguard for craftsmanship, efficiency, and safety alike.