In modern manufacturing and maintenance operations, drilling is one of the most basic and frequently performed tasks. Among the wide variety of drilling tools, the HSS Twist Drill Bit (High-Speed Steel Twist Drill Bit), with its outstanding performance and broad adaptability, has become an indispensable "universal key" for engineers, technicians, and craftsmen alike.

1. Core Applications of HSS Twist Drill Bits: The Foundation of Precision Drilling

The primary purpose of HSS is to achieve efficient and precise round-hole drilling. Its signature spiral flute design plays multiple critical roles:

Chip Removal Channel: During cutting, the spiral flutes act like a high-speed highway, quickly evacuating chips from the hole, preventing clogging, scratching the hole wall, or even causing the drill bit to jam or break.

Coolant/Airflow Channel: When machining high-hardness or high-toughness materials, the flutes provide a direct path for coolant or compressed air to reach the cutting tip, significantly reducing the impact of high temperatures on the drill bit's lifespan and machining quality.

Enhanced Stability and Accuracy: The scientifically designed helix angle not only ensures smooth chip evacuation but also enhances drill stability during high-speed rotation, which is key for high-precision hole machining.

Whether in precision machinery manufacturing, mold processing, automotive maintenance, pipeline installation, furniture production, or DIY projects, HSS play a fundamental and crucial role with their efficient and reliable drilling capabilities.

2. Versatile Material Compatibility: Exploring the HSS Drill Bit's Material Spectrum

"Can bits work on metals, wood, and plastics?" — The answer is yes. However, this does not mean it performs "perfectly" or has the same lifespan on every material. Its versatility is derived from the intrinsic properties of HSS:

Metals: This is the primary domain for HSS drill bits. They can effectively machine various carbon steels, alloy steels, stainless steels (with proper speed and cooling), cast iron, aluminum alloys (pay attention to chip removal and sharpness to prevent sticking), and copper alloys (watch out for softening). They are particularly cost-effective for high-efficiency drilling of medium-to-low hardness metals.

Wood: Drilling wood is relatively easy for HSS bits. The sharp edges cleanly cut through wood fibers, producing smooth hole walls. However, for some hardwoods, the high-temperature hardness of HSS is not critical, and woodworking-specific bits (e.g., twist bits, hole saws) may offer better chip removal and tear prevention.

Plastics: HSS bits are also suitable for common plastics (PVC, acrylic, nylon, ABS, etc.). Key factors include controlling speed and applying appropriate feed pressure. Excessive speed or pressure can cause plastics to melt, stick to the bit, or deform the hole wall. Using a sharp bit at low speed with light feed is essential for successful drilling.

3. Efficient Material Reference for HSS Drill Bits

The table below summarizes the main material categories that HSS twist drill bits can effectively machine, along with key considerations:

| Material Category |

Specific Examples |

Machining Performance |

Key Usage Notes |

| Ferrous Metals |

Low/medium carbon steel, tool steel |

Excellent; highly efficient and cost-effective |

Ensure proper cooling, select appropriate speed and feed |

| Stainless Steel |

304, 316 |

Good, but more challenging |

Use lower speed, sufficient coolant, stable feed to avoid work hardening; cobalt HSS bits preferred |

| Cast Iron |

Gray cast iron, ductile iron |

Good |

Usually dry drilling is fine; protect against dust |

| Non-Ferrous Metals |

Aluminum alloys, copper alloys, brass, bronze |

Good to excellent |

Maintain sharp cutting edge to prevent sticking; pay attention to chip removal and cooling; prevent softening of copper alloys |

| Engineering Plastics |

PVC, acrylic, nylon, ABS, polycarbonat |

Good |

Low speed! Light feed to avoid melting/sticking; remove tangled chips promptly |

| General Wood |

Softwoods (pine), hardwoods (oak, walnut) |

Good |

Wood-specific bits may perform better in chip removal and tear prevention, but HSS bits are versatile enough |

| Composites |

Laminates, fiberglass-reinforced plastics (special coating/material required) |

Limited |

Cutting edges wear very quickly; special geometry or coating needed; lifespan of standard HSS bits significantly reduced |

4. Performance and Features: Pillars of Efficient Machining

The wide applicability of bits across multiple fields stems from their core performance advantages:

Excellent Hot Hardness: This is the essence of HSS material. Even under the high temperatures generated during drilling (up to approximately 600°C), the bit can maintain sufficient hardness and strength for extended periods without deformation or softening. Compared with ordinary carbon steel bits, its durability is significantly improved.

Outstanding Wear Resistance: HSS material inherently resists abrasion, allowing the bit to maintain sharpness longer when machining abrasive materials such as metals and wood.

Good Toughness: Under proper usage conditions, HSS bits can withstand certain impacts and vibrations, reducing the risk of chipping or breaking. This makes them particularly suitable for handheld drills or scenarios with relatively unstable operating conditions.

High Cutting Edge Sharpness: Through precision grinding, HSS bits achieve extremely sharp cutting edges, which is crucial for producing smooth hole walls, especially in plastics and wood.

Cost-Effectiveness: In metalworking, HSS bits offer an excellent balance between cost and performance compared to carbide bits, making them one of the most economical choices for mass production and routine maintenance.

5. Material and Manufacturing: The Source of Performance

High-Speed Steel (HSS) is not a single material but a family of high-alloy tool steels. Its superior performance derives from a combination of complex chemical composition and heat treatment processes:

Core Composition: Mainly includes high percentages of Carbon (C), Tungsten (W), Molybdenum (Mo), Chromium (Cr), Vanadium (V), and often Cobalt (Co).

Tungsten/Molybdenum: Provide hot hardness and wear resistance.

Chromium: Significantly improves hardenability and wear resistance.

Vanadium: Refines grain structure, enhancing wear resistance and toughness.

Cobalt: Greatly enhances hot hardness and wear resistance (used in high-performance cobalt HSS such as M35, M42).

Key Manufacturing Processes:

1.Smelting and Forging/Rolling: Ensures material purity, uniform composition, and dense structure.

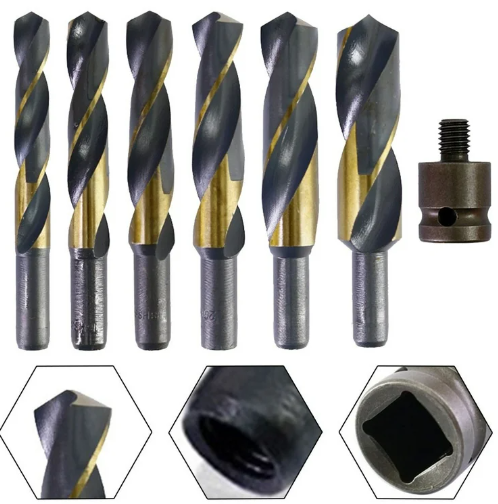

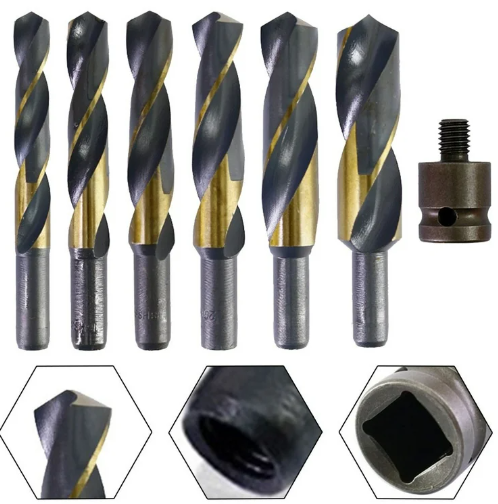

2.Precision Geometric Forming: Through rolling, grinding, or fully ground processes, critical geometric parameters are precisely shaped, including point angle (commonly 118°/135°), helix angle, and flute width. Fully ground bits usually offer higher precision and surface finish.

3.Quenching and Tempering: Core steps for imparting hardness and toughness. Controlled heating, holding time, and cooling medium (e.g., oil quench or staged salt bath quenching), followed by multiple precise tempering cycles, produce the desired microstructure (tempered martensite matrix with dispersed carbides) and hardness (typically HRC 63–67).

4.Surface Enhancement (Optional): To improve wear resistance and reduce friction, surface treatments can be applied, such as:

Steam/Oxidation Treatment: Forms a dense Fe₃O₄ oxide layer, enhancing rust resistance and lubrication.

Coatings (e.g., TiN, TiAlN): Significantly improve surface hardness, wear resistance, and heat resistance, extending drill life several times. Coatings usually appear gold-colored (TiN) or bluish-purple (TiAlN).

6. Maintenance and Usage Tips: Extend Lifespan, Enhance Efficiency

Proper care and usage can maximize the performance of HSS drill bits and significantly extend their service life:

Maintain Sharpness: A dull drill bit is a killer of both efficiency and quality! If drilling becomes difficult, generates excessive heat, produces rough hole walls, or emits unusual noises, inspect the cutting edges immediately. Use an appropriate drill grinder or send it to a professional for regrinding to restore tip symmetry and sharp cutting edges, paying special attention to the secondary cutting edges.

Cooling and Lubrication Are Essential:

Metal Drilling (especially steel and stainless steel): Always use cutting fluids (oil-based or water-based emulsions). They effectively cool the drill and workpiece, reduce friction, assist in chip evacuation, and prevent work hardening. Stainless steel drilling requires ample cooling.

Cast Iron, Brass, Bronze: Dry drilling is usually acceptable, but dust protection is necessary.

Aluminum and Magnesium Alloys: Use kerosene or specialized cutting fluids to prevent chip adhesion.

Plastics: Typically, no coolant is needed, but low drilling speed helps control temperature. For deep holes or heat-sensitive plastics, compressed air can be used for auxiliary cooling.

Proper RPM and Feed Force:

Excessive speed: Causes overheating, accelerates wear, and may soften the drill.

Too low speed: Reduces efficiency and can lead to rubbing rather than cutting, increasing wear.

Too little feed: Leads to surface friction instead of cutting, accelerating edge wear.

Excessive feed: May cause chipping or breakage, especially when drilling through or with small-diameter bits.

Reference: Always consult drilling parameter charts provided by the material or drill supplier, or use an online drill speed calculator. Generally, harder materials require lower speeds; smaller-diameter bits allow higher maximum RPMs.

Ensure Stability: Securely clamp the workpiece to prevent wobbling or shifting during drilling. Using drill jigs or center punches can improve accuracy and prevent the bit from wandering.

Chip Management: When drilling deep holes, periodically withdraw the bit to remove chips, preventing clogging in the flutes that can cause overheating, jamming, or breakage.

Proper Storage: Store drill bits by category in dedicated boxes or racks to avoid collisions that can damage cutting edges.

7. Industry Trends and Future Developments

As new materials emerge and machining precision requirements increase, it technology continues to evolve:

High-Performance Materials: The use of cobalt-rich HSS (e.g., M42) and powder metallurgy HSS (PM-HSS) is increasing. These steels feature a more uniform microstructure and finer carbide particles, resulting in higher hardness, hot hardness, and toughness.

Advanced Multilayer Nanocoatings: TiAlN, AlCrN, and other coatings are continually advancing, offering denser structures, stronger adhesion, and superior heat resistance (up to 900°C or higher), significantly extending tool life and efficiency in high-speed, dry, or hard material machining.

Optimized Geometry: Drill tip geometry (e.g., S-point, multi-facet tips) and helix angles are being optimized for specific materials such as stainless steel, aluminum alloys, and composites to improve chip evacuation, reduce cutting forces, enhance hole quality, and prolong tool life.

Integration with Smart Manufacturing: Drill condition monitoring, intelligent grinding, and digital management tools help achieve predictable drilling performance and efficient maintenance.

HSS twist drill bits, a stalwart in machining, maintain their position as the go-to tool for fundamental hole-making due to their outstanding overall performance, wide material compatibility, and excellent cost-effectiveness. From robust steel to precision plastics and everyday wooden components, HSS bits are ubiquitous. By mastering their core applications, understanding performance limits, following proper usage and maintenance practices, and keeping up with material and process innovations, engineers and technicians can fully unlock the potential of this "industrial universal key," achieving efficient, precise, and high-quality machining.For both large-scale manufacturing workshops and individual studios, selecting a reliable HSS supplier and continuously applying and optimizing drilling techniques remain key foundations for improving productivity and product quality.