1. From Steel Blades to Carbide — The Turning Point of the Cutting Tool Era

In the fields of mechanical processing and construction assembly, the evolution of cutting tools is often underestimated. Traditional high-carbon steel saw blades once dominated early machining applications. However, with the growing use of hard materials and composite panels, conventional blades can no longer meet modern production requirements for high efficiency and precision.

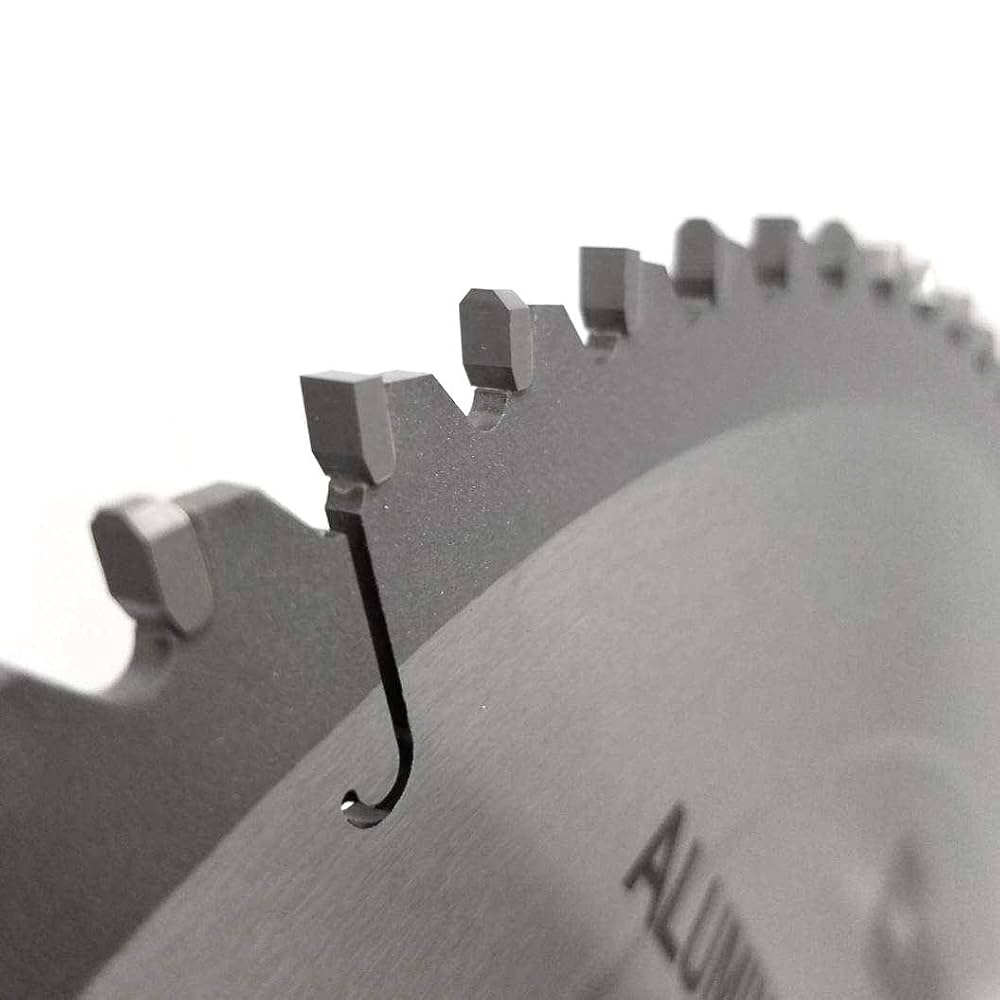

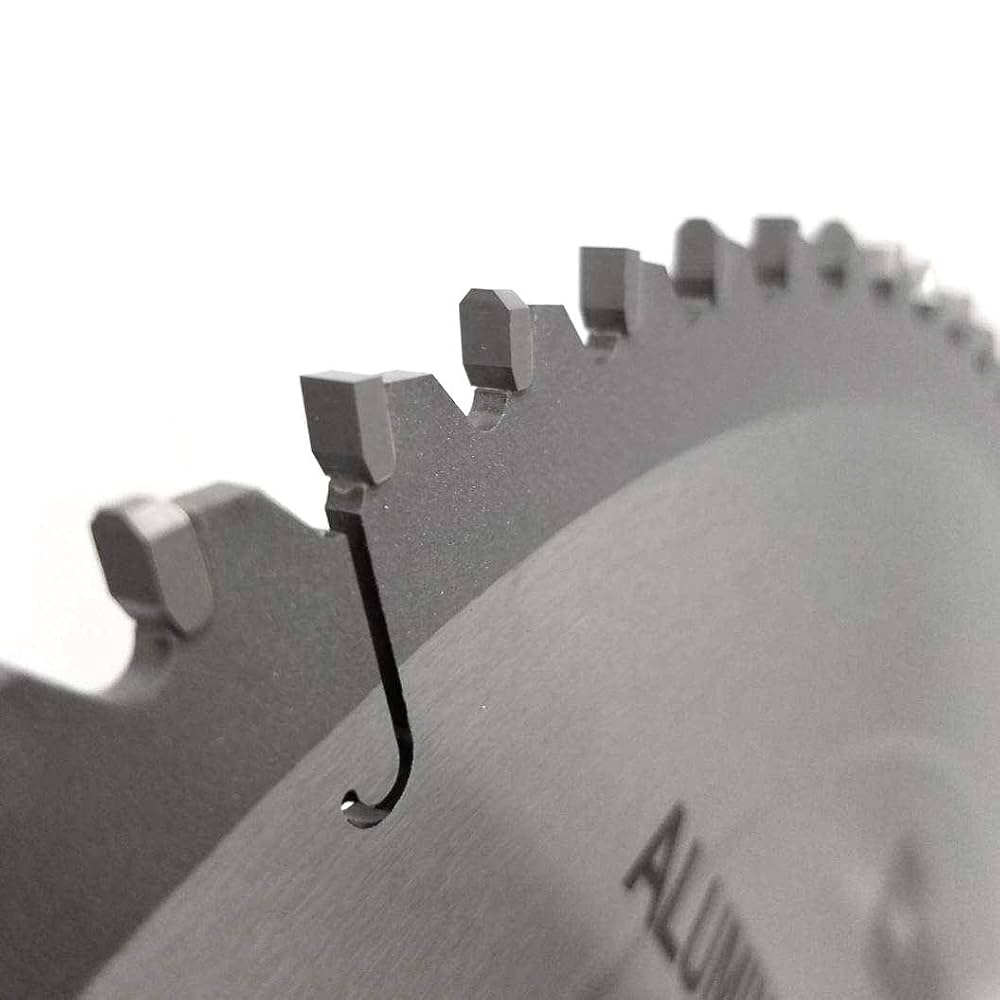

The emergence of the TCT (Tungsten Carbide Tipped Circular Saw Blade) marks a key turning point in this evolution. Its defining feature lies in its carbide-tipped teeth, made of tungsten-cobalt alloys — significantly harder, more heat-resistant, and longer-lasting than ordinary steel.

In industrial practice, a high-quality TCT is more than just a tool — it represents the efficiency of a production line and the precision of finished components.

2. Why Do Tungsten Carbide Teeth Improve Cutting Efficiency?

When we ask, "Why choose a Saw Blade?" the answer goes far beyond "sharpness."

Tungsten Carbide (TCT) is a sintered material known for its extreme hardness and thermal stability. With hardness close to that of diamond, it maintains a sharp edge even under high-speed, long-duration cutting conditions.

| Performance Indicator |

High-Speed Steel Blade |

TCT Circular Saw Blade |

| Hardness (HV) |

800–900 |

1600–2000 |

| Heat Resistance |

≤ 600°C |

≤ 1000°C |

| Average Service Life |

1× |

4–8× |

| Applicable Materials |

Wood, Soft Plastics |

Wood, Aluminum, Steel, Composites |

TCT not only cut faster but also maintain precision and edge sharpness over time, significantly reducing replacement frequency and maintenance costs.

3. From Woodworking to Metal Processing

Throughout industrial history, every leap in cutting technology has meant a new wave of productivity. The development path of the TCT is a perfect example — evolving from its origins in woodworking to applications in metals, aluminum, and composites, it has become a true "multi-purpose cutting solution" across industries.

The Woodworking Era: Balancing Precision and Efficiency

Wood was among the first materials to be industrially processed. Traditional woodworking blades made of carbon or high-speed steel were low-cost but prone to wear, overheating, and deformation. They often caused burning, discoloration, or splintered edges.

The arrival of the TCT transformed woodworking from an "experience-based" craft into a "science-based" process.

Cleaner cuts: Tungsten carbide tips remain sharp under high-speed rotation, preventing wood fiber tearing.

Longer lifespan: High wear resistance allows for continuous operation with fewer blade changes.

Higher dimensional accuracy: Enables millimeter-level precision when paired with automated feeding systems.

Wider material compatibility: Suitable for solid wood, plywood, MDF, and particle board.

Today's smart woodworking production lines commonly adopt the TCT saw + automatic panel line model, boosting both productivity and product uniformity.

Crossing into Metal Processing: The Dual Challenge of Hardness and Stability

When cutting moved from wood to metal, the demands increased dramatically. Metals are denser, tougher, and less conductive — causing rapid tool wear or even tooth breakage in conventional blades.

However, overcame these challenges through their high-hardness and high-toughness design.

Process Innovation:

Metal-cutting TCT blades feature negative rake angles to reduce cutting resistance, specialized tooth spacing to prevent material jamming, and precision brazing to ensure even stress across each tooth. Some advanced models apply PVD coatings (e.g., TiN, TiAlN) for improved wear and heat resistance, maintaining stability even at several thousand RPM.

Expanded Applications:

Today, TCT are used in:

Aluminum profile cutting (for construction, automotive, and solar frame components);

Steel tube and stainless steel cutting (for mechanical structures and precision parts);

Copper, brass, and conductive materials;

Composite and hard plastic processing.

Their cold-cutting, low-burr, low-noise performance has led them to replace abrasive wheels and conventional HSS blades in many industrial settings.

The Core of Cross-Material Evolution: Intelligent Blade Engineering

The TCT 's ability to span multiple materials comes from its structural and manufacturing evolution.

| Technical Aspect |

Woodworking |

Metal Processing |

| Tooth Geometry |

Positive rake, fine pitch |

Negative rake, wide pitch |

| Blade Body Thickness |

Lightweight, thin |

Reinforced, anti-vibration |

| Material Traits |

High sharpness, low-temperature cutting |

High hardness, high heat resistance |

| Coating |

None or anti-rust |

TiN, TiAlN, CrN coatings |

| Cutting Speed |

3000–6000 rpm |

1000–3500 rpm |

| Heat Dissipation |

Laser tension slots |

Multi-slot cooling holes |

Each improvement aims at the same goal: maintaining cut quality and stability under more demanding conditions.

For example, in aluminum processing, optimized tooth geometry minimizes burrs; in steel cutting, cold-cutting prevents discoloration and preserves weldability.

From a Single Tool to a System Solution: The New Manufacturing Mindset

The popularity of TCT has reshaped how manufacturers view the cutting process.

In woodworking plants, it's "the heart of the panel line."

In metal plants, it's "the control center of high-speed cutting systems."

Modern manufacturing emphasizes tool systemization:

Blade selection must consider not only material but also spindle speed, clamping structure, and cooling conditions.

Customized tooth geometry ensures optimal performance for each production scenario.

Digital monitoring tracks wear conditions and predicts replacement intervals in advance.

Thus, the TCT is evolving from a passive tool into an active, intelligent node within the manufacturing chain — connecting precision, efficiency, and data-driven optimization.

4. The Dual Demand for High Precision and High Throughput

Manufacturing is entering an era defined by "precision + productivity."

As equipment continues to advance, the performance of the saw blade itself has become one of the key limiting factors.

Industry experts point out:

"The value of a TCT lies not only in the hardness of its material but also in how well it matches the machine's spindle speed, feed rate, and vibration control."

This means that modern cutting technology emphasizes the synergy between the saw blade and the entire system.

High-precision equipment requires the blade body to maintain excellent balance, consistent tooth geometry, and stable welding. Otherwise, even the best carbide tips may lead to runout, vibration, noise, or burn marks on the cut surface.

Therefore, the core of TCT manufacturing is evolving from "single-material superiority" to "integrated process optimization."

5. Key Technological Trends in TCT Circular Saw Blade Manufacturing

In the industry, the manufacturing of a TCT typically involves multiple stages — from base plate cutting and tip brazing to balance calibration and laser marking. With the adoption of precision machinery and automated inspection systems, these processes continue to evolve.

(1) High-Precision Brazing Technology

The bonding method between the tungsten carbide tip and the steel body has advanced from traditional silver brazing to high-frequency induction welding, resulting in stronger adhesion and reduced heat-affected zones.

(2) Stress Control and Dynamic Balancing

Any imbalance in internal stress during high-speed operation can cause blade vibration or deviation.

Modern manufacturing employs laser fine-tuning and dynamic balance correction, ensuring that the blade remains stable even at thousands of revolutions per minute.

(3) Surface Coating and Wear Resistance Treatment

Some high-end models apply Titanium Nitride (TiN) or Chromium Nitride (CrN) coatings to further enhance wear resistance and oxidation stability, extending the operational lifespan in demanding environments.

6. Balancing Cutting Performance and Cost Control

When users choose a TCT , their priorities are not just about cutting faster — but about cutting steadily, lasting longer, and reducing costs.

In real-world production, a high-quality saw blade provides multiple cost advantages:

| Cost Factor |

Conventional Blade |

TCT Circular Saw Blade |

| Replacement Frequency |

High |

Low |

| Downtime for Maintenance |

Long |

Short |

| Cutting Energy Consumption |

Relatively High |

Lower |

| Finished Product Scrap Rate |

Occasional chipping |

Minimal |

| Total Life Cycle Cost |

High |

Reduced by 20–40% (depending on conditions) |

Hence, although the initial investment may be slightly higher, the total cost of ownership of a TCT Blade is significantly lower over its operational lifespan.

It achieves the ideal balance between efficiency, precision, and economic value.

7. Long Service Life Equals Green Manufacturing

As global manufacturing moves toward carbon neutrality and sustainable production, the cutting tool industry is also undergoing transformation.

Thanks to its exceptional durability, the TCT Circular Saw Blade reduces the frequency of tool replacements and waste disposal. From a life-cycle perspective, this means higher material utilization and lower carbon emissions.

Additionally, some production lines are now experimenting with recycled tungsten powder recovery technologies, extending the material's circular use.

This signals a future where TCT cutting tools will pursue not only performance and precision — but also sustainability and environmental responsibility.

8. "Data-Driven Tools" in Smart Manufacturing

With the widespread adoption of digitalized production, tool condition monitoring and lifespan prediction have become emerging trends in the cutting industry.

In the future, the TCT is expected to integrate with intelligent cutting systems through sensors and data acquisition technologies to enable:

Real-time monitoring of tool wear;

Automatic adjustment of feed speed;

Predictive replacement scheduling;

Creation of a comprehensive "tool health profile."

These data-driven tools will make manufacturing more precise and energy-efficient, while enabling enterprises to achieve intelligent quality control and predictive maintenance.

9. From Material Revolution to Manufacturing Upgrade

The rise of the TCT represents more than an advancement in material science—it signifies a transformation in manufacturing philosophy.

It marks the shift from experience-based operations to data-driven decision-making, and from manual replacement to intelligent prediction.

In the industrial chains of the future, the saw blade will no longer be viewed merely as a consumable item, but as a critical component influencing production rhythm, energy efficiency, and finished product quality.

Amid the global drive toward more efficient, precise, and sustainable manufacturing, the TCT is poised to become a representative tool of the new era of industrial cutting.