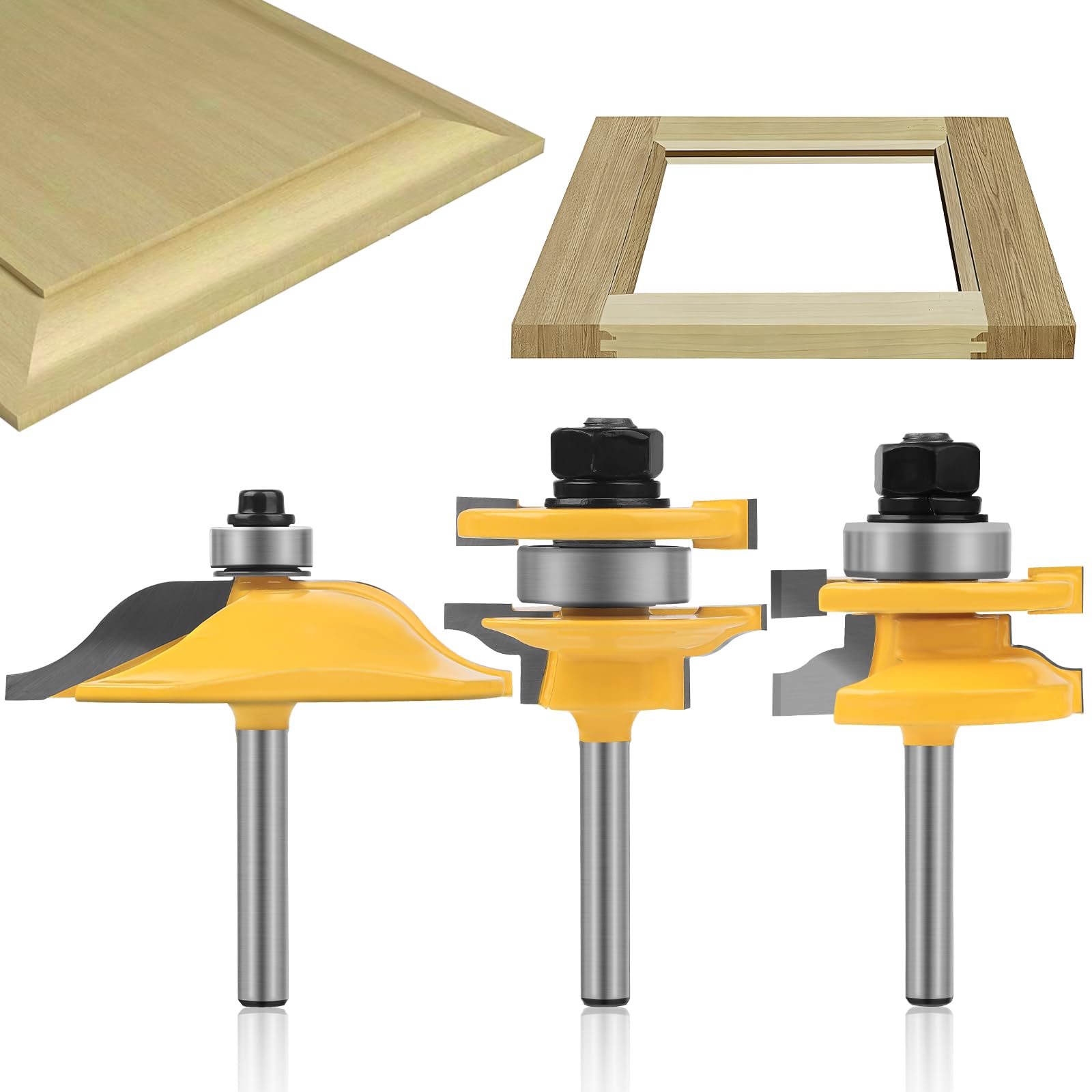

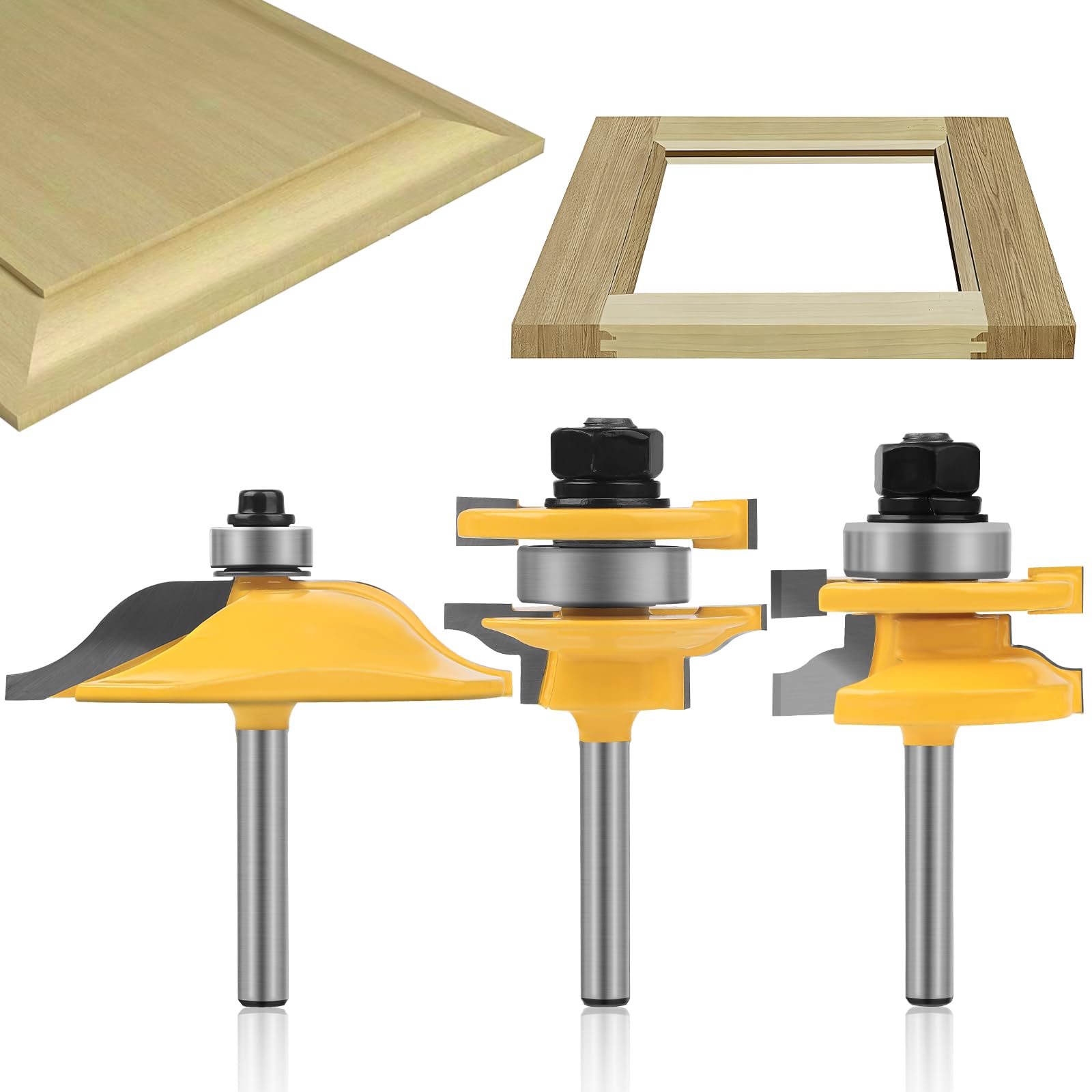

Woodworking router bits are the core cutting tools of woodworking machinery. By rotating at high speed, their sharp edges carve, groove, and trim wood surfaces with extreme precision. In essence, they are replaceable cutting heads that transform design drawings into three-dimensional wooden creations. From furniture joinery to decorative moldings, every detail relies on the precise control of this "wood shaper."

Working Principle: The Precision Dance of Rotational Cutting

Router bits are driven by motors that rotate the spindle at speeds often exceeding 20,000 RPM. With micro-level accuracy, the sharp cutting edges remove wood fibers in a seamless process consisting of three key actions:

1.Cutting – The edge penetrates the wood fibers, forming the desired contour.

2.Chip Removal – Spiral flutes guide sawdust out quickly and efficiently.

3.Shaping – Controlled toolpaths create complex surfaces with precision.

This entire process resembles three-dimensional sculpting, where the bit's trajectory directly determines the accuracy and smoothness of the finished product.

Main Types and Application Scenarios (with Classification Table)

| Type |

Typical Cutter Shape |

Core Application |

| Straight Bit |

Cylindrical straight edge |

Grooving, boring, square cuts |

| Trim Bit |

Bearing-guided wheel |

Edge profiling, template copying |

| Round-over Bit |

Rounded cutting edge |

Furniture corners, decorative edges |

| Joinery Bit |

Specialized profiles |

Tenon and mortise joinery |

| Edge/Molding Bit |

Multi-curve profiles |

Carving, hollow patterns, artistic design |

Different types of router bits determine cutting effects and application scope, making selection the first key consideration in woodworking projects.

Material Comparison: Carbide vs. High-Speed Steel

Carbide-Tipped Bits (Mainstream Choice)

Advantages: 3–5 times higher wear resistance, suitable for hardwoods and laminated boards.

Craftsmanship: Tungsten carbide tips are brazed onto a steel body, balancing hardness and toughness.

Durability: Provides 50+ hours of continuous use, with multiple resharpening cycles supported.

High-Speed Steel (HSS) Bits (Phasing Out)

Limitations: Prone to heat and dulling during continuous cutting; suitable only for softwoods.

Cost: Lower upfront price, but frequent replacements lead to higher long-term costs.

Test Data: When cutting oak, carbide-tipped bits lasted up to 120 minutes before significant wear, while HSS bits showed clear dulling after only 35 minutes.

Advantages and Disadvantages of Woodworking Router Bits

Advantages

1.Versatility

Can be used for grooving, trimming, chamfering, carving, joinery, and many other woodworking operations.

Different bit types enable decorative profiling, structural machining, and fine carving.

2.High Precision

Ensures clean cutting lines and neat edges, making it ideal for precision woodworking and furniture manufacturing.

3.Material Compatibility

Suitable for solid wood, plywood, MDF, composite panels, and even certain plastics and acrylics.

4.Efficiency Improvement

When paired with high-speed power tools, cutting speed is greatly increased, significantly boosting productivity.

5.Reusability

Most carbide-tipped bits can be professionally resharpened, extending service life and reducing long-term costs.

Disadvantages

1.Higher Initial Cost

Carbide-tipped bits are more expensive compared to ordinary cutters, requiring greater upfront investment.

2.High Equipment Requirements

Must be paired with routers or CNC machines of suitable power and speed, otherwise poor cutting performance or tool damage may occur.

3.Strict Maintenance Needs

Dull bits must be resharpened or replaced promptly to avoid burning, chipping, or even dangerous kickbacks.

4.High Safety Demands

At high rotation speeds, improper installation or incorrect feed direction can damage workpieces or cause operator injury.

5.Skilled Operation Required

Different bit types and materials demand varying feed rates and cutting depths, requiring experienced operators for best results.

Selection Guide: Four Steps to the Ideal Router Bit

1.Match the Cutting Task

Use straight bits for grooving, edge-forming bits for trimming, and molding bits for decorative carving.

2.Confirm Shank Compatibility

Common shank sizes include 6mm, 8mm, and 12mm, which must exactly match the router collet.

Tip: Use a vernier caliper to measure the collet inner diameter for precision.

3.Choose the Right Cutting Edge for the Material

Fewer teeth (2–4) for hardwoods to improve chip clearance.

More teeth (6–8) for laminated boards to achieve a smoother finish.

4.Quality Identification Checklist

Edge: Carbide tips should be seamlessly brazed, with no pores or cracks.

Balance: Bit should rotate smoothly without vibration or abnormal noise.

Coating: Titanium-coated bits can extend service life by up to 20%.

Recommended Bit Characteristics by Application

| Application |

Recommended Bit Features |

| Fine carving |

Small diameter, multi-tooth, carbide material |

| High-speed grooving |

Large diameter, fewer teeth, straight bit |

| Decorative shaping |

Molding bits, chamfer bits, round-over bits |

Safe Operation Manual for Woodworking Router Bits

Installation Guidelines

Insert the bit shank only after power is disconnected, ensuring the collet grips at least 80% of the shank length.

Tighten using two wrenches (to prevent slipping or rotation). Torque should not exceed the rated value of the equipment.

Operating Techniques

Feed Direction: Move the bit against the grain (see Fig.1) to avoid tear-out along the wood fibers.

Preventing Burn Marks:

Control feed speed (recommended 0.5–2 meters/minute).

Use step-by-step cutting, with each pass removing no more than 3 mm of material.

Preventing Edge Chipping:

Apply protective tape when machining end grain.

For laminated boards, cut from the laminate surface toward the substrate.

Maintenance Procedures

| Step |

Key Points of Operation |

| Cleaning |

Use a stiff-bristle brush with special solvent to remove resin residues. |

| Anti-Rust |

Apply light machine oil; avoid corrosive cleaners. |

| Storage |

Hang bits individually on a rack to prevent edge collisions. |

| Resharpening |

Inspect cutting edges after every 8 hours of use; send for professional resharpening if dull. |

Industry Outlook

With the rise of custom furniture, smart home solutions, and precision woodworking, the demand for woodworking router bits continues to grow. Future industry trends will focus on:

More wear-resistant cutting materials.

A wider variety of specialized molding bit designs.

Safer and more intelligent installation and application methods.

It is foreseeable that router bits will play an even greater role in improving production efficiency and product quality, becoming an essential tool in the modern woodworking industry chain.