In metal processing, wood production, and composite material manufacturing, the efficiency of cutting tools acts as the driving engine for product quality and production output. Traditional carbon steel blades often face limitations such as rapid dulling and short service life, which become more evident when cutting high-strength materials or performing precision tasks. In contrast, Tungsten Carbide-Tipped (TCT) Circular Saw Blades, with their revolutionary material structure and design innovation, are rapidly becoming the benchmark of performance in the industrial cutting field.

Carbide Vanguard: Material Technology Empowering a New Era of Cutting

The core strength of TCT circular saw blades lies in their precise structural design:

Blade Body: Made of high-tension special alloy steel, offering excellent fatigue resistance and structural stability, capable of withstanding the enormous centrifugal force of high-speed rotation.

Cutting Teeth: Tipped with tungsten carbide composites, reaching a hardness of over HRA90, their wear resistance surpasses high-speed steel by 5–10 times.

Protective Coating: Premium models are treated with nano-scale anti-corrosion coatings (such as chromium nitride or diamond-like carbon), reducing friction heat, preventing material adhesion, and enhancing rust resistance.

This combination of toughness and sharpness provides dual advantages: a strong, deformation-resistant body and ultra-durable carbide teeth. As a result, the blades excel in cutting metals (aluminum, copper alloys), hardwood, laminates, PVC, and even fiberglass-reinforced plastics.

Tooth Geometry: The Efficiency Code for Precise Cutting Applications

Cutting performance largely depends on the scientific design of the tooth geometry. Main profiles include:

| Tooth Design |

Application |

Key Advantage |

| Flat Top (FT) |

Cross-cutting wood, particle boards |

Smooth cuts, chip-free edges |

| Alternate Top Bevel (ATB) |

Plywood, veneered panels |

Sharp entry, reduced tearing |

| Triple Chip Grind (TCG) |

Laminates, non-ferrous metals |

Smooth chip removal, anti-sticking |

| High-ATB |

Hardwood, nail-embedded wood |

Impact resistance, extended lifespan |

Tooth count also determines efficiency and finish quality:

Low tooth count (24–40): Deep, fast cuts with high chip removal, ideal for rough work and soft materials.

Medium tooth count (60–80): Versatile balance between speed and surface finish.

High tooth count (90–120): Ultra-precise cuts with mirror-like surfaces, perfect for decorative materials and thin-walled metals.

Vibration Control and High-Speed Stability: The Hidden Guardians of Cutting Precision

TCT blades achieve stable high-speed cutting through three core technologies:

1.Stress Relief Design: Laser-cut expansion slots release internal stress, reducing thermal deformation.

2.Damping and Noise Reduction: Special vibration-damping slots or patches absorb harmonic oscillations, reducing noise by up to 40%.

3.Dynamic Balancing: Each blade is calibrated to G2.5 or higher accuracy, ensuring smooth operation above 8000 RPM.

Tests show that optimized TCT blades improve vibration control by over 50% compared to conventional products, significantly reducing edge chipping risks caused by material trembling during cutting.

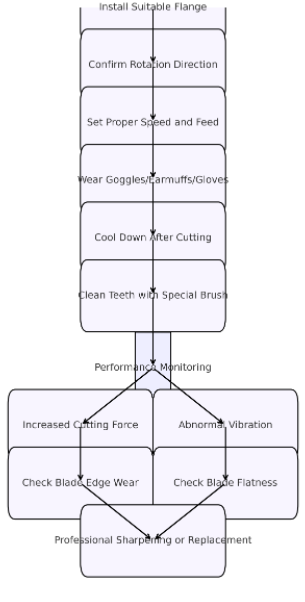

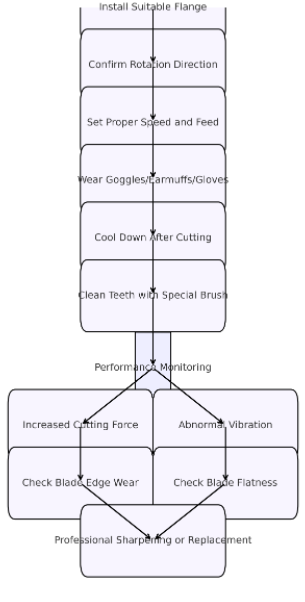

Full Lifecycle Management: Safety Principles from Installation to Disposal

Standardized Operating Procedures as the Foundation of Safety Assurance:

Extended Service Life and Scrap Standards

Routine Maintenance: Regularly clean residues with resin cleaner to prevent carbonized buildup that reduces cutting efficiency.

Wear Indicators: If surface roughness suddenly increases, unusual odors appear, or cutting time rises by 30%, sharpening is required.

Professional Sharpening: Maximum grinding allowance per carbide tooth is 0.3 mm, with total regrinding limited to three times.

Safe Disposal: Immediate replacement is necessary if the blade body deforms, tooth seats crack, or consecutive teeth break.

Storage Requirements

Store blades hanging or lying flat in a dry environment. Avoid stacking pressure to prevent deformation. Use cushioning materials to protect contact surfaces.

Installation and Usage Guidelines

Correct Installation:

Ensure the blade is intact, free of cracks or missing teeth.

Confirm proper rotation direction and tighten the arbor nut securely.

Match the saw's speed with blade specifications.

When to Sharpen or Replace:

Significant drop in cutting efficiency.

Severe wear on blade surface or tooth edges.

Abnormal noise or vibration during cutting.

Safety Tips:

Always wear goggles and protective gloves.

Avoid fracture risks during high-speed cutting.

Properly dispose of broken blades to prevent injury.

Storage and Maintenance

TCT blades should be stored in dry, shaded areas away from corrosive liquids to prevent oxidation. Avoid impact, and clean teeth regularly to maintain sharpness. Applying rust-proof oil further extends blade life.

| Storage Requirement |

Maintenance Method |

| Dry and ventilated |

Prevent rust from moisture |

| Shaded and cushioned |

Avoid deformation or collisions |

| Regular cleaning |

Remove cutting debris, apply rust-proof oil |

Why TCT Blades Are the Cutting Solution for Modern Manufacturing

Versatile Adaptability: One blade fits multiple applications—metal, wood, and composites.

Long-Lasting Performance: Service life exceeds that of standard steel blades by more than five times, reducing downtime.

Precision Cutting Quality: High tooth density delivers near-mirror finishes, eliminating secondary polishing.

High-Speed Capability: Supports 8,000–12,000 RPM operation, accelerating production efficiency.

Safety and Cost Efficiency: Anti-chipping design reduces risks while long life lowers material costs.

As advanced manufacturing increasingly demands precision and efficiency, TCT circular saw blades have evolved from a single-purpose tool into a core component of intelligent production lines. The fusion of material science, fluid dynamics, and precision engineering is redefining the boundaries of industrial cutting—accelerating product flow while building a technological safeguard for quality and safety in every rotation.