The TCT Circular Saw Blades for Aluminium and Plastic (Negative) by Fangda Holding Co., Ltd. are meticulously designed to offer optimal performance for cutting aluminium, non-ferrous metals, and polymeric materials. With their innovative Flat-Triple Chip Tooth design and negative cutting angle, these blades excel at handling soft materials, ensuring smooth chip removal and precise cutting.

Key Features & Benefits:

Designed for Cutting Aluminium and Non-Ferrous Metals: These saw blades are specifically designed to handle the demands of cutting aluminium, non-ferrous metals, and polymeric materials, making them an ideal choice for industries such as aerospace, automotive, and plastics manufacturing.

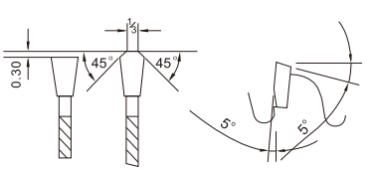

Flat-Triple Chip Tooth Design with Negative Cutting Angle: The Flat-Triple Chip Tooth design with a negative cutting angle ensures smoother, more efficient cuts, reducing the likelihood of material distortion or surface damage. This tooth configuration is particularly effective for materials that require a precise and clean finish.

Enhanced Chip Removal: The blades are specially engineered for chip removal, which is especially beneficial when cutting softer materials. The negative cutting angle promotes better chip flow and reduces the risk of material build-up, improving both the cut quality and tool lifespan.

Versatile for Soft Materials: These blades are perfect for cutting soft materials such as aluminium, plastics, and other polymeric materials that need precise cuts without sacrificing performance. This makes them an excellent choice for a variety of applications in different industries.

Use with Sawblade Over Workpiece: To achieve the best results, it is recommended to use these blades with the sawblade positioned over the workpiece to be cut. This enhances cutting stability, allowing for smoother and more accurate cuts with minimal effort.

Applications:

Ideal for cutting aluminium, non-ferrous metals, and a variety of polymeric materials.

Suitable for use in industrial and commercial settings, particularly for manufacturing, fabrication, and assembly tasks involving soft metals and plastics.

Great for applications that require chip removal and clean cutting edges, such as the aerospace, automotive, and plastics industries.

Why Choose Fangda's TCT Circular Saw Blades:

Efficient Chip Removal: The negative cutting angle and tooth design are optimized for chip removal, making it easy to cut through soft materials like aluminium and plastics with minimal material build-up.

Enhanced Durability: With Tungsten Carbide Tips (TCT), these blades provide exceptional durability, maintaining their sharpness and cutting performance over extended periods of use.

Precision Cuts: Achieve clean, smooth cuts with minimal burrs or surface imperfections, enhancing the overall quality of the finished product.

Reliable Performance: Whether cutting aluminium, plastics, or other non-ferrous materials, these blades offer consistent performance and are designed for long-lasting use in demanding industrial environments.

These TCT Circular Saw Blades for Aluminium and Plastic (Negative) are the ideal choice for professionals seeking high-performance, precision cutting solutions for soft metals and polymeric materials. With their advanced design and ability to handle tough cutting jobs, these blades improve cutting efficiency and extend the tool's life.