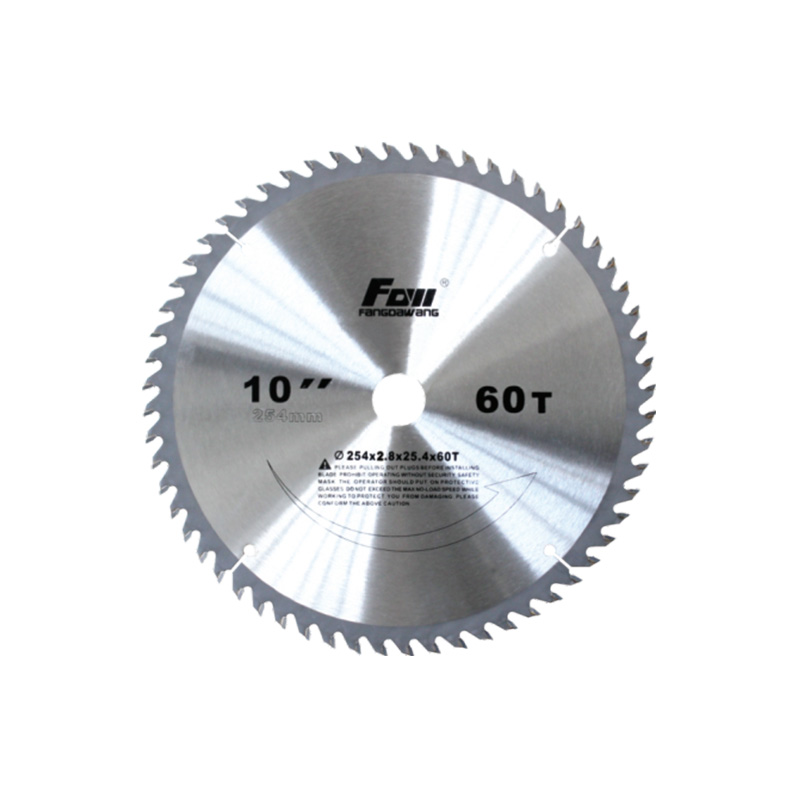

What Are TCT Circular Saw Blades for Solid Wood?

TCT Circular Saw Blades are designed with tungsten carbide tips that provide superior hardness, sharpness, and durability. These blades are specifically built for cutting through solid wood, making them a go-to choice for industries such as furniture manufacturing, construction, and woodworking.

Incorporating ATB (Alternate Top Bevel) teeth ensures that the blade provides clean and precise cuts, especially when working with solid wood. Fangda's TCT circular saw blades are engineered to deliver the best results, whether you're using a rip saw or a crosscut saw.

Key Features of Fangda's TCT Circular Saw Blades for Solid Wood

Premium Tungsten Carbide Tips:

Fangda's TCT blades are equipped with tungsten carbide tips, which provide exceptional wear resistance and ensure sharpness for extended periods, even during heavy-duty cutting.

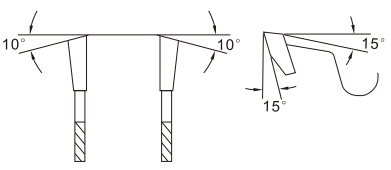

Teeth Type: ATB (Alternate Top Bevel):

The ATB teeth design enhances the blade's ability to make smooth, clean cuts, particularly beneficial for solid wood. This design also helps to minimize splintering on both the face and edges of the cut wood.

High-Speed Performance:

Designed to work with both rip saws and crosscut saws, these TCT blades perform exceptionally well at high rotational speeds, allowing for efficient cutting with reduced downtime for maintenance or blade changes.

Durability and Longevity:

Thanks to the use of premium materials and advanced manufacturing technology, Fangda's TCT circular saw blades offer long service life, reducing the need for frequent replacements and improving cost-efficiency over time.

Precision Cutting for Solid Wood:

Ideal for cutting hardwoods, softwoods, and plywood, these blades ensure clean cuts and accurate edges, essential for projects like furniture making, cabinetry, and construction.

Advantages of TCT Circular Saw Blades for Solid Wood

Superior Cutting Performance:

TCT blades from Fangda allow for high precision with smooth cuts, even when handling the hardest solid woods. The carbide tips ensure excellent cutting performance, reducing the need for post-processing.

Longer Blade Life:

Due to the hardness of tungsten carbide, these blades stay sharper for longer periods, minimizing the frequency of blade replacements. This leads to significant cost savings over time, especially in high-volume production settings.

Minimal Maintenance:

Fangda's TCT saw blades require less maintenance compared to traditional saw blades. The carbide-tipped teeth can withstand the stress of continuous cutting without losing their edge or causing excessive wear to the wood.

Reduced Splintering:

The ATB teeth configuration allows for cleaner, smoother cuts, reducing the risk of splintering and chipping, which is particularly important when working with high-quality wood that requires a refined finish.

Versatile for Different Applications:

Fangda's TCT circular saw blades are not only suited for solid wood cutting but also plywood, and laminated wood, making them ideal for a variety of woodworking applications such as furniture production, cabinet making, and construction.

Applications of TCT Circular Saw Blades for Solid Wood

Furniture Manufacturing:

Furniture makers benefit from the precision cuts provided by Fangda's TCT blades, which are essential for smooth edges and accurate fitting in furniture production, especially for pieces requiring intricate designs.

Construction:

In construction, where solid wood is frequently used for framing, decking, and other structural purposes, Fangda's TCT circular saw blades offer the cutting precision needed for high-quality results in demanding projects.

Woodworking:

Woodworkers, both professional and hobbyist, rely on TCT circular saw blades for smooth cuts and reliable performance. Whether it's crosscutting or ripping, these blades are perfect for woodturning, shaping, and crafting.

Cabinet Making and Joinery:

When creating high-end cabinetry or joinery, Fangda's TCT blades ensure that every cut is perfect, enhancing both the functionality and aesthetic of the end product.

Why Choose TCT Circular Saw Blades from Fangda Holding Co., Ltd.?

Fangda Holding Co., Ltd. stands out as a leader in the manufacture of TCT circular saw blades for solid wood. Here's why choosing Fangda's products can benefit your business:

Precision Manufacturing: Fangda employs state-of-the-art manufacturing techniques to produce high-precision saw blades that meet the rigorous demands of solid wood cutting applications.

Reliability and Durability: With years of experience in the industry, Fangda ensures that their TCT blades deliver consistent, high-performance results over time.

Customization Options: Fangda offers a range of customized solutions, tailoring saw blades to meet the unique needs of individual customers, including specific tooth configurations and sizes.

Comprehensive Customer Support: Fangda provides comprehensive after-sales support, ensuring that customers receive the necessary maintenance, installation guidance, and technical support for optimal performance.