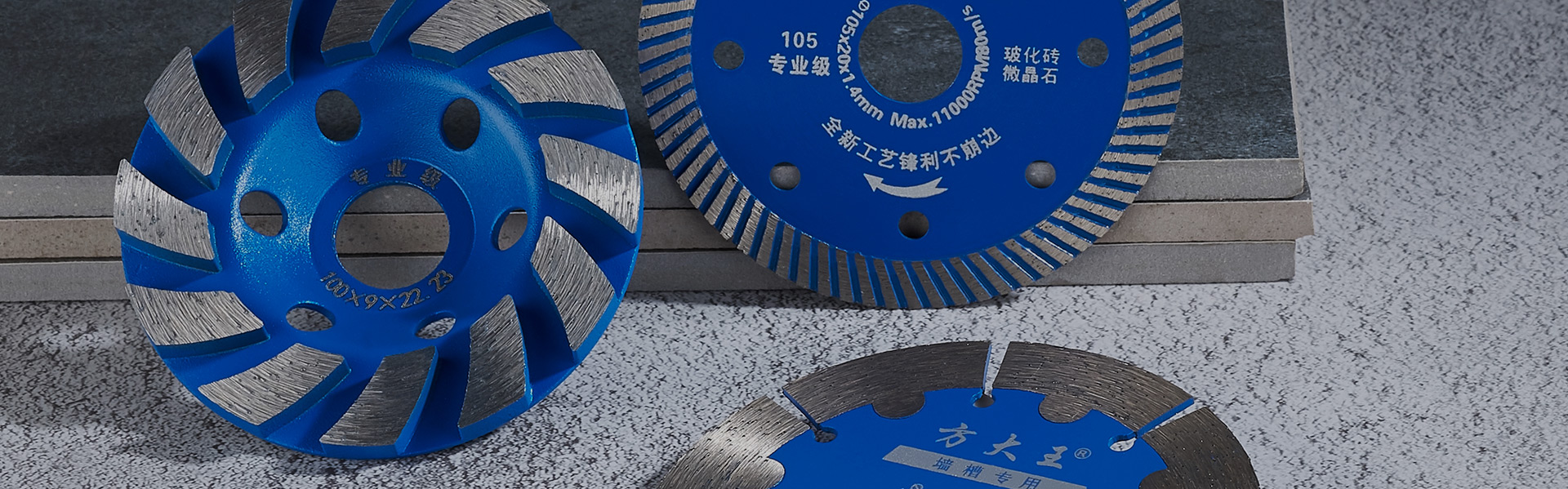

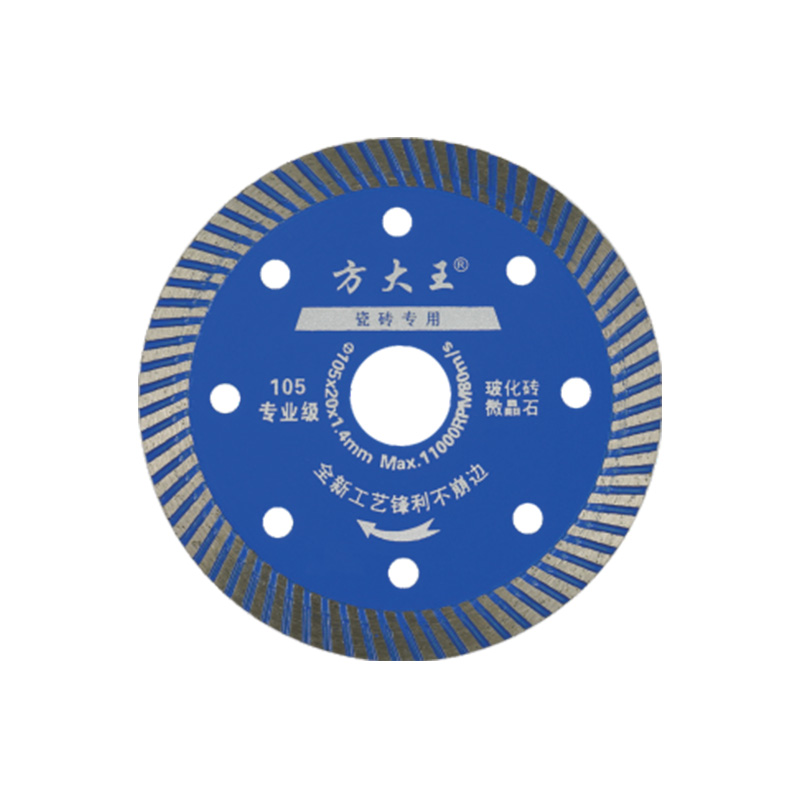

The Turbo Rim Diamond Cutting Disc gets the job done fast on tough stuff like stone, concrete, ceramics, or vitreous tile. It's got great accuracy and holds up well over time, whether you're a pro on a site or just tinkering at home. These blades slice through hard surfaces quick and neat, giving you nice, even cuts without hassle.

Product Features

Turbo Rim Design: This rim setup cranks up the speed and cuts down shakes, so you get clean slices with less sweat.

Versatile Cutting: Great for hacking through stone, concrete, ceramic, or tile on all sorts of jobs.

Tough Build: Diamond tech keeps it going strong, even on the roughest materials.

Heat Control: The rim pulls away heat to stop overheating and keep the blade kicking longer.

Sharp Edges: Built to skip chips and leave straight lines, ideal for brickwork, tiling, or building gigs.

Wet or Dry: Handles both setups fine, no matter the spot or stuff you're cutting.

Advantages

Faster Work: Rim design speeds things up on hard jobs, saving you time.

Less Jitter: Keeps vibrations low for easier handling and better grip.

Lasts Longer: Quality diamonds and glue mean fewer swaps.

Smooth Results: No rough spots or chips, especially on tile – looks pro every go.

All-Rounder: One blade tackles stone to tile without extras.

Heat Smarts: Dumps heat to avoid bends under pressure, stays safe.

Flexible Use: Wet or dry, it fits any work area.