- Home

- Products

- Carbide Tipped Masonry Drill Bits

- Carbide Tipped Masonry Drill Bit Sets

- Steel Chisels

- Hole Saws

- Router Bit Sets

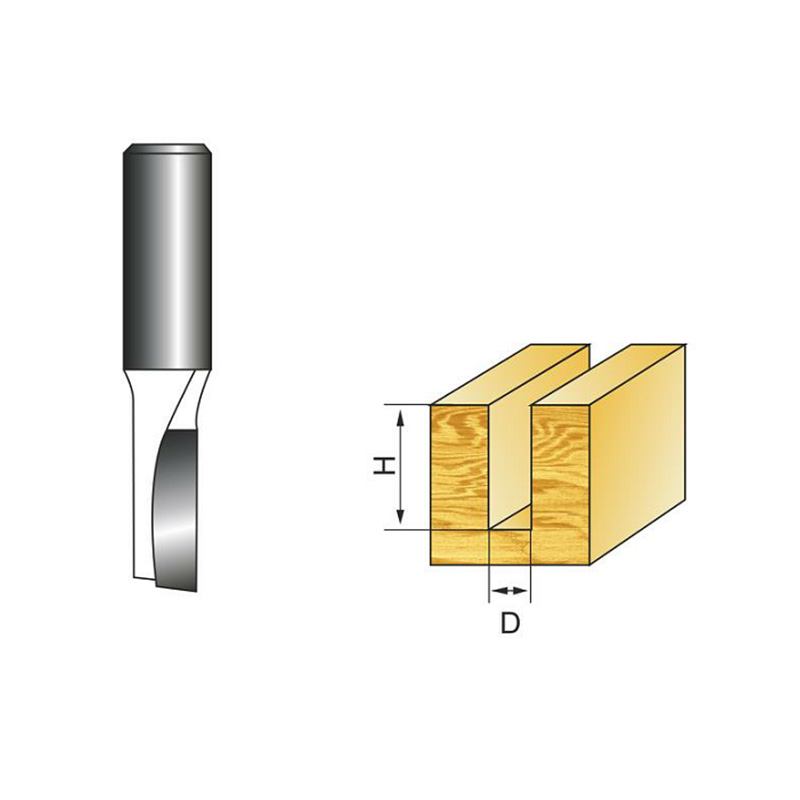

- Router Bits

- TCT Circular Saw Blades

- Diamond Cutting Disc

- HSS Straight Shank Twist Drill

- Hole Saw For Wood

- Hole Saw For Metal

- Multi-Function Drilling Series

- Pneumatic Nail Gun

- Pneumatic Screwdriver

- Pneumatic Spray Gun

- Pneumatic Air Tube

- Pneumatic Fitting

- Diamond Engineering Thin Wall Drill

- Abrasives Disc Cutting Wheel

- Other Drilling And Sawing Tools

- About

- CAPABILITIES

- Service

- News

- Contact

- Carbide Tipped Masonry Drill Bits

- Carbide Tipped Masonry Drill Bit Sets

- Steel Chisels

- Hole Saws

- Router Bit Sets

- Router Bits

- TCT Circular Saw Blades

- Diamond Cutting Disc

- HSS Straight Shank Twist Drill

- Hole Saw For Wood

- Hole Saw For Metal

- Multi-Function Drilling Series

- Pneumatic Nail Gun

- Pneumatic Screwdriver

- Pneumatic Spray Gun

- Pneumatic Air Tube

- Pneumatic Fitting

- Diamond Engineering Thin Wall Drill

- Abrasives Disc Cutting Wheel

- Other Drilling And Sawing Tools