Elevate Your Woodworking: A Comprehensive Guide to Step Beading Router Bits

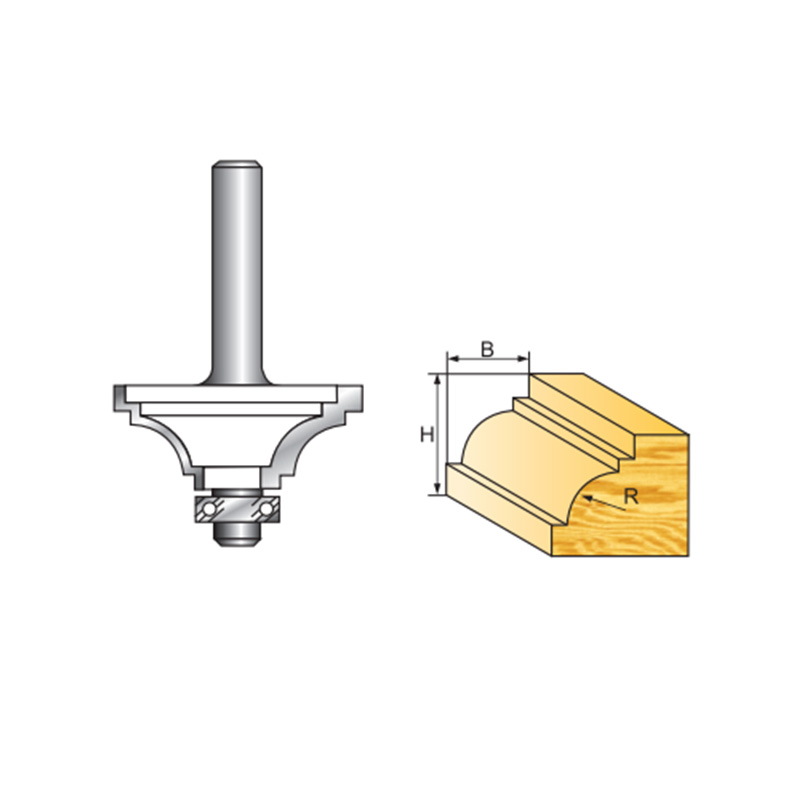

If you're into woodworking, whether it's building cabinets, crafting furniture, or adding fancy trim to shelves, a step beading router bit is one of those tools that can really elevate your projects. It's designed to cut decorative edges with a stepped bead profile—think of it as creating a series of rounded beads stacked in steps along the edge of your wood. This gives a classic, elegant look that's perfect for period-style pieces or just adding some visual interest to plain boards. Unlike a simple roundover bit, the step beading version adds layers, making the edge pop with depth and shadow.

These bits are typically made from high-speed steel or, better yet, carbide-tipped for longer life and sharper cuts. The carbide versions hold up well against hardwoods like oak or maple, resisting dulling even after repeated use. Most come with a 1/4-inch or 1/2-inch shank to fit standard routers, and they often include a guide bearing at the bottom. That bearing rides along the wood's edge, helping you maintain consistent depth without wandering off course. It's a game-changer for freehand routing or when using a router table.

The profile usually features multiple beads—say, two or three steps—each with a smooth curve. For example, a common size might have a 1/8-inch radius on the smallest bead, stepping up to 1/4-inch or more. You can find them in various overall diameters, from about 1 inch to over 2 inches, depending on how bold you want the bead. Some bits even allow for adjustable depths, so you can tweak the step height by changing the router's plunge setting.

Safety-wise, these bits have anti-kickback designs built in, with the carbide teeth arranged to reduce grabbing. Always use them at the right speed—around 16,000 to 24,000 RPM for smaller bits—to avoid burning the wood or chattering. And don't forget dust collection; routing beads kicks up a lot of fine particles.

In practice, step beading bits shine in applications like picture frames, where the stepped edge adds sophistication without overwhelming the design. Or on drawer fronts, they create a subtle hierarchy that draws the eye. Pros in cabinet shops love them for door panels, as they mimic traditional molding without needing a full shaper setup. For hobbyists, they're accessible—pair one with a basic router and some scrap wood to practice, and you'll get clean results fast.

Durability is key here. A good carbide bit can handle hundreds of linear feet before needing sharpening, and many can be resharpened a few times. Look for brands with precision-ground bodies to minimize vibration, which leads to smoother finishes. Some advanced models have shear angles on the flutes for cleaner shearing action, reducing tear-out on figured woods.