| Part No. |

Size |

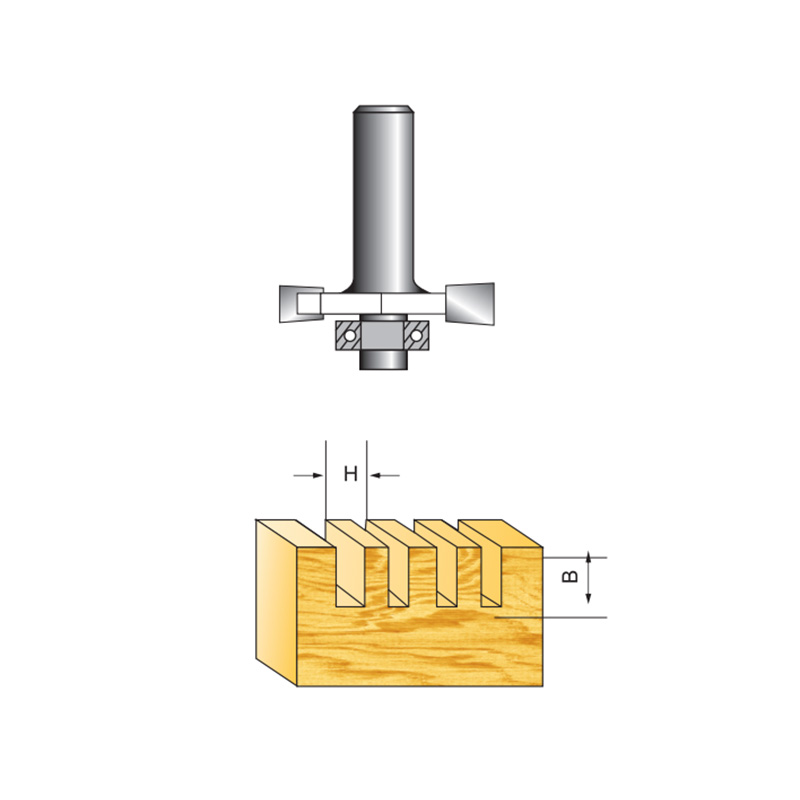

D |

H |

B |

| FD14001 |

1/4×3/32 |

31.75 |

2.38 |

8.4 |

| FD14002 |

1/4×1/8 |

31.75 |

3.17 |

8.4 |

| FD14003 |

1/4×5/32 |

31.75 |

3.96 |

8.4 |

| FD14004 |

1/4×3/16 |

31.75 |

4.76 |

8.4 |

| FD14005 |

1/4×1/4 |

31.75 |

6.35 |

8.4 |

| FD14006 |

1/4×5/16 |

31.75 |

7.96 |

8.4 |

| FD14007 |

1/4×3/8 |

31.75 |

9.52 |

8.4 |

| FD14008 |

1/4×1/2 |

31.75 |

12.7 |

8.4 |

| FD14017 |

1/2×5/8 |

31.75 |

15.9 |

8.4 |

| FD14018 |

1/2×3/4 |

31.75 |

19.05 |

8.4 |

| FD14019 |

1/2×7/8 |

31.75 |

22.2 |

8.4 |

| FD14020 |

1/2×1 |

31.75 |

25.4 |

8.4 |

How It Works

The T Type Round Bit With Bearing operates by rotating at high speeds, cutting the material along the edges to create smooth, rounded contours. The integrated bearing makes it easier to follow the contours of the material, ensuring that the cut remains even and smooth throughout the process. It is ideal for achieving flawless edges on wood, MDF, plastic, and other materials used in woodworking and furniture making.

Key Features & Applications

Edge Profiling: Ideal for creating clean, rounded edges for various woodworking projects, including furniture, shelves, and doors.

Trimming & Shaping: The bit is perfect for trimming excess material or shaping components to fit precisely together, particularly when working with intricate designs or curves.

Consistent Results: The built-in bearing provides stability and precision, resulting in consistent cuts and reduced chances of error.

Versatility: This bit can be used on different materials such as wood, MDF, and plastic, making it a versatile tool for various woodworking tasks.

User-Friendly: Its design makes it easy to use, making it suitable for both professional woodworkers and DIY enthusiasts.

The T Type Round Bit With Bearing is an essential tool for any woodworking project that requires smooth, rounded edges and fine detailing. It is designed to provide professional-grade results with ease, ensuring that your projects stand out with clean and polished finishes. Whether you are working on furniture, cabinetry, or home improvement projects, this tool is sure to enhance the quality and precision of your work.