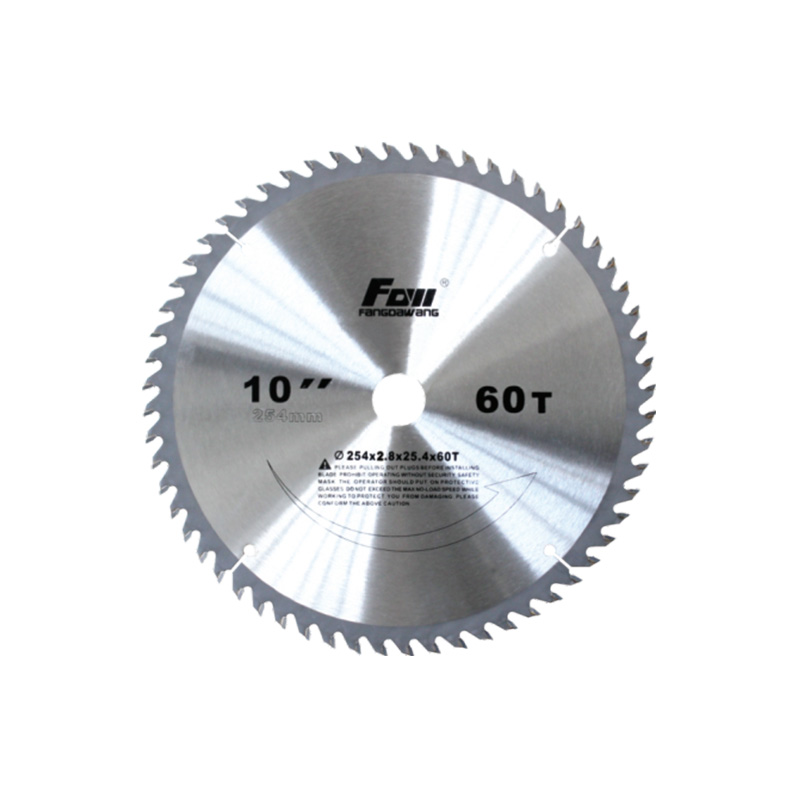

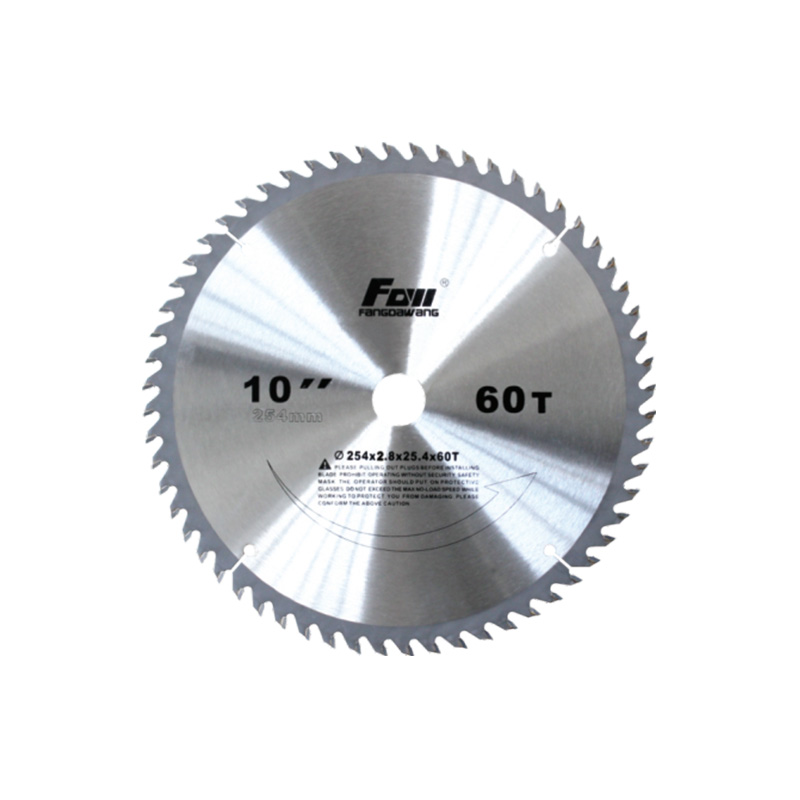

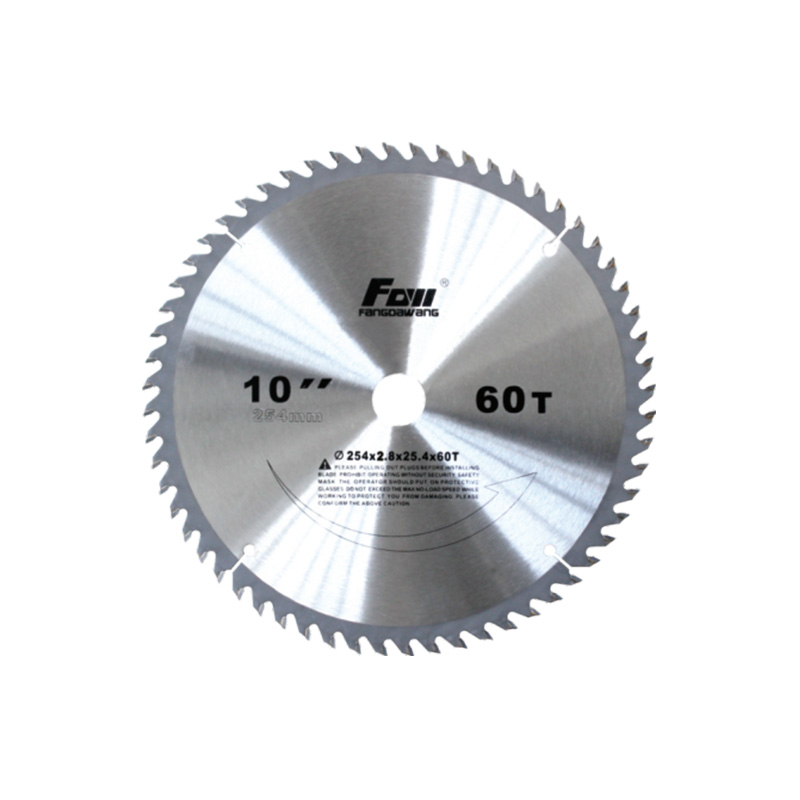

TCT Circular Saw Blades: High-Performance Cutting Solutions

At Fangda Holding Co., Ltd, we specialize in producing premium TCT Circular Saw Blades designed for professionals who require precision, durability, and high-efficiency performance in their cutting tasks. With Tungsten Carbide Tips (TCT), these blades are ideal for a variety of applications, from woodworking to metalworking, delivering exceptional results with each cut.

Advantages of TCT Circular Saw Blades

Enhanced Durability: The Tungsten Carbide tips on these blades significantly increase their hardness and wear resistance, providing a much longer lifespan compared to traditional steel blades. This results in fewer replacements and lower long-term costs.

Efficient Cutting: TCT blades are designed for high-speed cutting, ensuring smoother, faster, and more efficient operations. They can tackle tough materials like hardwoods, metals, and plastics without losing cutting performance, allowing for consistent, high-quality cuts over time.

Precision and Clean Cuts: With a sharper edge and more accurate tooth geometry, TCT circular saw blades produce cleaner, finer cuts, which is critical for projects requiring exacting standards, whether in furniture making, construction, or metal fabrication.

Versatility Across Materials: TCT blades are versatile, capable of cutting a wide range of materials including wood, MDF, plywood, non-ferrous metals, plastics, and composite materials. Their adaptability makes them essential in various industries such as manufacturing, construction, and woodworking.

Industries Using TCT Circular Saw Blades

Fangda Holding Co., Ltd provides TCT circular saw blades for a diverse range of applications:

Woodworking: Perfect for cutting through various types of wood, including hardwood, softwood, MDF, and plywood.

Metalworking: Well-suited for cutting non-ferrous metals like aluminum, copper, and brass.

Construction: Ideal for cutting construction materials, including panels, flooring, and other building components.

Plastics and Composites: Efficient in cutting plastics and composite materials used in various manufacturing processes.

Why Choose Fangda's TCT Circular Saw Blades?

At Fangda Holding Co., Ltd, we focus on producing high-quality TCT circular saw blades that are durable, reliable, and tailored to meet the needs of different industries. Our state-of-the-art production facility, combined with stringent quality controls, ensures that every blade performs at its best, even under the most demanding conditions.

What sets us apart:

Customization: We offer various tooth designs, sizes, and specifications to suit specific cutting needs.

High-Quality Materials: Only the finest tungsten carbide is used for superior performance and longevity.

Global Reach: We serve businesses around the world with OEM and ODM capabilities.

When it comes to high-performance cutting tools, TCT Circular Saw Blade from Fangda Holding Co., Ltd offer the perfect balance of durability, precision, and efficiency. Whether you're working with wood, metal, or plastic, our blades deliver exceptional results that improve productivity and reduce operational costs.